How To Install Transom Windows Above Interior Doors

Adding transom windows to cased openings in your abode tin can instantly requite information technology that custom craftsman home feel. This unproblematic DIY tutorial will show you how!

One of the first things we did when we moved into our spec home was to identify areas were we could hands change the whole experience of the house past adding some transom windows to cased openings. We now have a total of vii transoms that I have added. In a non-load bearing cased opening this procedure is adequately straight forward and I desire to teach you lot how to practise it!

Tools and Supplies (click for links)

- Matte Pocketknife

- Crowbar

- Small sledge hammer

- Reciprocating saw

- Tabular array saw

- Miter saw

- Nail gun

- Razor scraper

- ane×8 pine trim board

- Pine lattice molding

- Custom transom window

First you lot have to detect out if the opening where you want to add together the transom is load bearing or non. If you take open wall pictures (like the 1 below) you tin easily tell if the wall with the opening is load begetting or not: a load begetting wall will take a thick structural header to a higher place the opening to transfer the load across the opening gap. A non-load bearing wall volition simply have a unmarried 2x material spanning the gap (as in the picture beneath).

If you have any question about whether or non the wall is load bearing, contact a professional for an assessment. Once confirmed that it is not load bearing, you can measure and purchase your transom. I measured the exact width of the cased opening betwixt the trim and subtracted a quarter of an inch. The height of the casing depends on your ceiling height and how low you want the bottom of the transom to be as you walk nether it. I propose that you lot keep at least 7 anxiety to the bottom of the transom. I purchased my transoms at Transoms Direct and they have full instructions on their site on how to go the measurements exact. They did a swell task of making high quality transoms and shipping them to me quickly. There are so many styles to chose from!

Later on that it is time for some demo! I started by taking off the casings from the front and dorsum of the opening. Then I removed the casing jamb. I saved all of these pieces because nearly of them tin exist used once again. And so I cut dorsum the drywall on both sides with my matte knife to expose the ii×iv framing that I needed to remove to install the transom. I used a reciprocating saw and modest sledgehammer to remove the framing. Depending on the last maximum height of the transom you may or may not have to add together a horizontal framing piece back in later you remove the verticals.

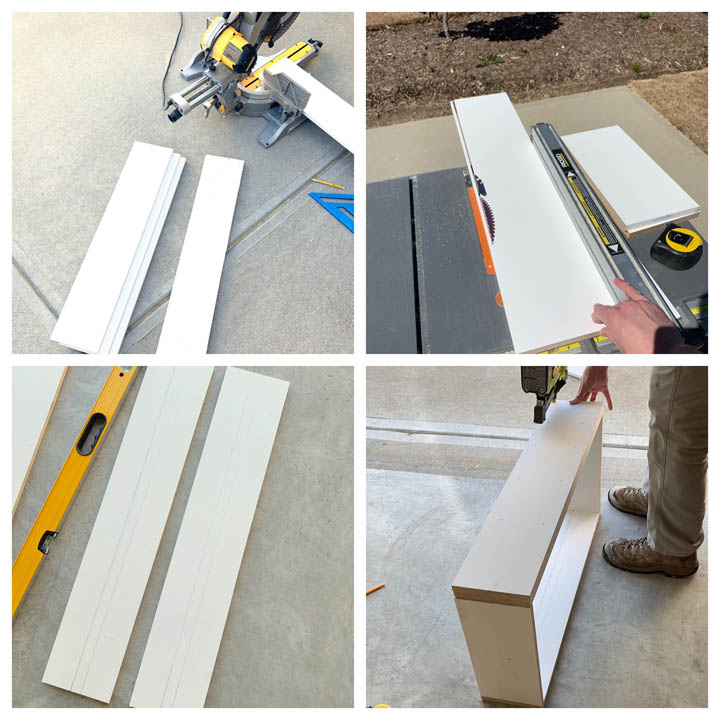

At present y'all take to make a jamb for the transom to sit in. The jamb supports the transom from both size and the way it constructed will change the overall feel of the transom. My structure of the jamb was as unproblematic equally possible. I started by ripping 1×8 pre-primed pino down to the width of the opening (in my instance 6″) on the tabular array saw. I and so used the miter saw to cutting pieces to make a box that fit the exterior dimensions of the transom. I used woods glue and my 18 gauge nail gun to secure the box. A window stop molding is needed to hold the transom in place inside of the jamb. I used the table saw to rip down 1x material into window stop strips that were three/iv″ x 1/2″ on the sides. I made pencil outlines all around the within of the jamb to betoken where the transom would sit (in my instance exactly in the middle) and this immune me to know where to install the window terminate.

I used my nail gun to install the window stop all the way around on ane side, mitering the corners. Afterwards information technology was in all the mode around, I dropped in the transom window! With the transom in identify I installed the other side of the window stop. Now the transom is supported on both sides and is stable all the way around.

The transom in the jamb has to have something to sit on, so the adjacent footstep is to make the opening jamb. To determine the height of the opening jamb, subtract the superlative of the transom jamb from the maximum opening pinnacle. I used spacers to continue the opening jamb plumb on both sides while I nailed it into place.

Afterward that you can bring in the transom in the jamb and carefully place information technology on pinnacle of the opening jamb. Line everything upward then blast the transom jamb to the opening jamb and into the walls.

After the jambs are all secured you have to add together the casings back to the forepart and back of the jambs.

I used a strip of lattice molding (2″x1/4″ bodily) to comprehend the front where the transom jamb and opening jamb came together.

After y'all fill the nail holes and caulk all the seams yous have to pigment the trim and the transoms. I always utilise the same color paint for both. The transoms are actually designed to be painted without taping the glass. The practical paint runs into the tiny gaps betwixt the drinking glass and the forest and makes a secure bond between the two and eliminates any glass rattling.

Using a brand new flat razor blade in a razor scraper you can score effectually the outside of the drinking glass and then scrape off the paint very hands. I did this scraping for this window unit in approximately 20 minutes full.

In i weekend you tin completely change the feel of your abode adding a transom to a cased opening. Relish your new space!

Want to run across videos of this process? Follow me on Instagram and click my "Transom Window" story highlight!

Reader Interactions

Source: https://philiporflop.com/transom-window/

Posted by: woolleyuple1987.blogspot.com

0 Response to "How To Install Transom Windows Above Interior Doors"

Post a Comment